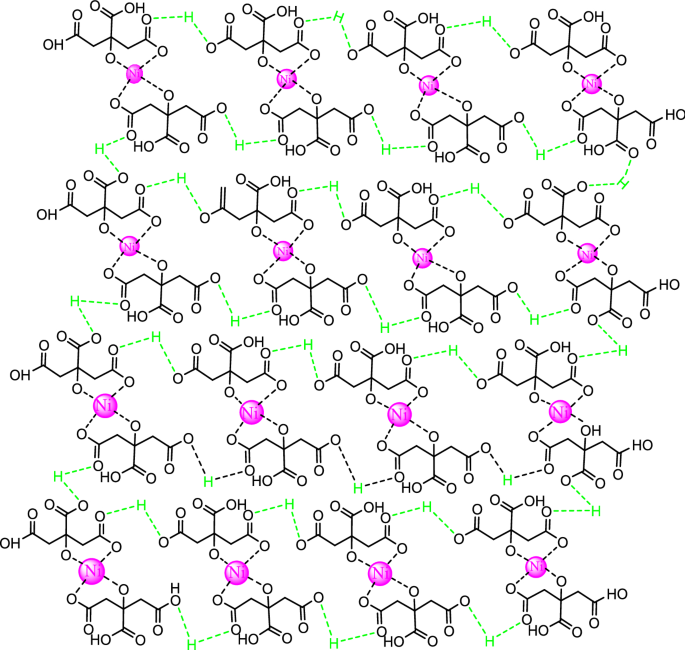

Ni–citric acid coordination polymer as a practical catalyst for multicomponent reactions Coordinative polymers (CP) are a subclass of Metal–organic frameworks (MOFs) with porous microstructures which have been widely synthesized in recent years and applied in various fields especially in catalysis science. In this work Coordinative polymers (CP) of nickel and citric acid (CA) was prepared as a new catalyst (Ni-CP) and applied in organic multicomponent reactions. The obtained catalyst was characterized by SEM, WDX, EDS, AAS, FT-IR, XRD and BET analysis. N2 adsorption–desorption isotherms indicate good BET surface area for Ni-CP; therefore can be employed as an efficient catalyst in multicomponent reactions for the synthesis of polyhydroquinoline and 2,3-dihydroquinazolin-4(1H)-one derivatives. Finally, this catalyst was recovered and reused several consecutive times. Multicomponent reactions (MCRs) have gained more attention in the last decade as a great and powerful strategy in the synthesis of natural products, medicinal chemistry and organic reactions1,2,3,4,5,6,7,8,9,10,11. Typically, MCRs are defined as one-pot reactions with more than two starting materials join to generate a desired single product of the reagent atoms1,12. Comparison to multistep reactions, MCRs offer a high atom economy, simple procedures, selectivity, environmental friendliness, time and energy saving8,9,13. In this regard various heterogeneous and homogeneous (Transition metals, transition metal complexes or supported metals) catalysts are employed in MCRs to increase selectivity and rate of the reaction4,14. For example, multicomponent reactions have been significantly extended using Coordinative polymers (CP)15. Coordinative polymers are commonly formed by transition metal ions and an organic multi-dentate ligand15,16. CP platforms with unique properties such as easy recoverability, large pore aperture, low density, high specific surface area, permanent nanoscale porosity and uniform structured cavities, have been used as ideal catalysts in MCRs and other applications such as drug delivery, gas storage, separation science, gas purification, sensing, optoelectronics, magnetism and luminescence17,18,19,20,21,22. In the continuation of the development of new CP catalysis in MCRs. Herein we report the synthesis of a new CP of nickel and citric acid and its catalytic activity in the synthesis of polyhydroquinoline and 2,3-dihydroquinazolin-4(1H)-one derivatives. Polyhydroquinolines and 2,3-dihydroquinazolin-4(1H)-ones have a wide range of biological properties and pharmaceutical activities23,24,25,26,27,28. For example, nifedipine, amlodipine and nicardipine are several biologically active compounds of polyhydroquinoline derivatives29,30. Besides, 2, 3-Dihydroquinazolin-4(1H) ones are known to possess diverse pharmacological actions31,32. For example, quinethazone, fenquizone, metolazone, evodiamine, afloqualone, methaqualone are several biologically active compounds of 2,3-dihydroquinazolin-4(1H)-one derivatives33,34,35. Also, 2-(2-hydroxy-phenyl)-4(3H)-quinazolinone (HPQ) was utilized in the detection of metal ions or act as a biosensor to scrutinize the Monoamine oxidases activity36,37,38,39.All chemicals and solvents employed in this work were purchased from Aldrich or Merck companies and used without further purification.Preparation of Ni-CPTo prepare Ni-CP, citric acid (1 mmol) was dissolved in water (2 mL) and, then, it was added to a solution of DMF (12 mL) containing 2 mmol of nickel nitrate. Afterward, the obtained mixture was transferred into a autoclave and heated at 160 °C for 1 day, which then cooled down and Subsequently washed with ethyl acetate. Finally, the Ni-CP product was dried at 60 °C in an oven (Fig. 1).Figure 1The topological structure of Ni-CP.General procedure for the synthesis of polyhydroquinoline in the presence of Ni-CPA mixture of various aromatic aldehydes (1 mmol), NH4OAc (1 mmol), dimedone (1 mmol), ethyl acetoacetate (1 mmol), and Ni-CP (5 mg), was refluxed in ethanol at 80 °C. Completion of the following reaction has been analyzed via TLC, Subsequent the reaction mixture was diluted with hot ethanol to dissolve the organic products, the catalyst was separated using simple filtration and the resultant unrefined solid products, was further purified through recrystallization in ethanol and dried to obtain a pure solid.General procedure for the synthesis of 2,3-dihydroquinazolin-4(1H)-ones in the presence of Ni-CPA mixture of various aromatic aldehydes (1 mmol), anthranilamide (1 mmol) and Ni-CP (6 mg), was refluxed in ethanol at 80 °C. Completion of the following reaction has been analyzed via TLC, Subsequent the reaction mixture was diluted with hot ethanol to dissolve the organic products, the catalyst was separated using simple filtration and the resultant unrefined solid products, was further purified through recrystallization in ethanol and dried to obtain a pure solid.Selected spectral data2-(4-Methoxyphenyl)-2,3-dihydroquinazolin-4(1H)-one (Table 5, entry 4)1H NMR (400 MHz, CDCl3): δH = 8.18 (s, 1H), 7.62–7.60 (d, J = 8 Hz, 1H), 7.42–7.41 (d, J = 4 Hz, 2H), 7.25–7.22 (t, J = 8 Hz, 1H), 7.00 (br, 1H), 6.95–6.93 (d, J = 8 Hz, 2H), 6.75–6.73 (d, J = 8 Hz, 1H), 6.68–6.65 (t, J = 8 Hz, 1H), 5.70 (s, 1H), 3.74 (s, 3H) ppm.2-(p-tolyl)-2,3-Dihydroquinazolin-4(1H)-one (Table 5, entry 3)1H NMR (400 MHz, CDCl3): δH = 8.23 (s, 1H), 7.63–7.61 (d, J = 8 Hz, 1H), 7.39–7.37 (d, J = 4 Hz, 2H), 7.25–7.22 (t, J = 4 Hz, 1H), 7.19–7.18 (d, J = 4 Hz, 1H), 7.05 (s, 1H), 6.76–6.74 (d, J = 8 Hz, 1H), 6.69–6.65 (t, J = 8 Hz, 1H), 5.72 (s, 1H), 2.29 (s, 3H) ppm.2-Phenyl-2,3-Dihydroquinazolin-4(1H)-one (Table 5, entry 1)1H NMR (400 MHz, CDCl3): δH = 8.27 (s, 1H), 7.62–7.60 (d, J = 8 Hz, 1H), 7.50–7.48 (d, J = 4 Hz, 2H), 7.40–7.34 (m, 3H), 7.25–7.22 (t, J = 8 Hz, 1H), 7.10 (s, 1H), 6.75–6.74 (d, J = 4 Hz, 1H), 6.68–6.65 (t, J = 8 Hz, 1H), 5.75 (s, 1H) ppm.Ethyl 2,7,7-trimethyl-4-(3-nitrophenyl)-5-oxo-1,4,5,6,7,8-hexahydroquinoline-3-carboxylate (Table 3, entry 8)1H NMR (400 MHz, CDCl3): δH = 9.24 (s, 1H), 7.97 (s, 2H), 7.61–7.51 (d, J = 40 Hz, 2H), 4.96 (s, 1H), 3.96 (s, 2H), 2.50–2.43 (m, 2H), 2.33 (s, 3H), 2.20–2.17 (d, J = 12 Hz, 1H), 1.99–1.96 (d, J = 12 Hz, 1H), 1.12–1.09 (t, J = 8 Hz, 3H), 1.00 (s, 3H), 0.82 (s, 3H) ppm.Ethyl 4-(4-methoxyphenyl)-2,7,7-trimethyl-5-oxo-1,4,5,6,7,8-hexahydroquinoline-3-carboxylate (Table 3, entry 3)1H NMR (400 MHz, CDCl3): δH = 9.00 (s, 1H), 7.05–7.03 (d, J = 8 Hz, 2H), 6.74–6.72 (d, J = 8 Hz, 2H), 4.78 (s, 1H), 3.97–3.95 (d, J = 8 Hz, 2H), 3.66 (s, 3H), 2.49 (s, 2H), 2.26 (s, 3H), 2.16–2.13 (d, J = 12 Hz, 1H), 1.98–1.94 (d, J = 16 Hz, 1H), 1.14–1.11 (t, J = 8 Hz, 3H), 1.00 (s, 3H), 0.88 (s, 3H) ppm.Herein coordination polymer of nickel and Citric acid (Ni-CP) is reported as an efficient catalyst in multicomponent reactions for the synthesis of polyhydroquinoline and 2,3-dihydroquinazolin-4(1H)-one derivatives. Ni-CP was characterized by AAS, EDS, WDX, SEM, TGA, XRD, FT-IR and BET analysis. The surface morphological features of synthesized Ni-CP were studied by scanning electron microscope. Figure 2 shows the SEM image of Ni-CP with a magnification of 5000. The instrumental parameters, accelerating voltage, spot size, and magnification and working distances are indicated on the SEM image. The results indicate that mono-dispersive and highly crystalline Ni-CP is obtained. The appearance of some particles is spherical shape. We can observe that the Ni-CP is highly agglomerated and they are essentially cluster of Ni-CP. The SEM picture indicates the size of polycrystalline particles. The observation of some larger Ni-CP may be attributed to the fact that Ni-CP tends to agglomerate due to their high surface energy and high surface tension of the ultrafine Ni-CP. The fine particle size results in a large surface area that in turn, enhances the Ni-CP catalytic activity. So, we can conclude that the prepared Ni-CP particles are in the nanometer range. The average diameter of the particle observed from SEM analysis is 30 nm, which is larger than the diameter predicted from X-Ray broadening.Figure 2The FT-IR spectrum of the citric acid had absorption bands in the regions of 1703 cm−1 and 1751 cm−1 respectively, which is related to the stretching vibration of the C=O bonds of aliphatic carboxylic acid groups (Fig. 3b). These absorption peaks were not observed in the spectra of the prepared Ni-CP, while the spectra of the Ni-CP presented two absorption peaks related to the vibration of the C=O bonds of aliphatic carboxylic acid groups at 1589 cm−1. The high shift to the lower wavenumber of the absorption peak of carbonyl demonstrates the existence of the metal coordination bonding and also confirms the complexation reaction between Ni and citric acid (Fig. 3c). In addition, the peaks at the region of 2855–2928 cm−1 can be regarded as the characteristic of the stretching vibrations of aliphatic C–H15. The presence of aliphatic C–H stretching vibration indicates that the organic ligand used in the final sorbent structure remained and was not destroyed. In addition, various peaks were presented such as 400–1000 cm−1 for Ni–O bonds and 3000–3600 cm−1 for OH of carboxylic acid40,41. Based on the FT-IR results, we can also observe that the Ni-CP obtained from Nickel Nitrate shows sharp characteristic peaks, suggesting the high crystalline nature of Ni-CP (Fig. 3).Figure 3FT-IR Spectrums of (a) Nickel nitrate, (b) citric acid and (c) Ni-CP catalyst.The elemental content of Ni-CP was obtained by EDS (energy-dispersive X-ray spectroscopy) analysis (Fig. 4). Based on the EDS results, the presence of oxygen (A%:45), carbon (A%:47), and as well as nickel (A%:8) species have been confirmed in the structure of the catalyst.Figure 4The homogeneous distribution of these elements has been studied by X-Ray Mapping (WDX analysis) in this catalyst which is shown in (Fig. 5). Also, the exact amount of nickel in the structure of this CP catalyst was calculated by atomic absorption spectroscopy (AAS) analysis which was found to be 2.07 × 10−3 mol g−1.Figure 5Elemental mapping of (a) oxygen, (b) carbon, and (c) nickel for Ni-CP.To investigate the porous nature and the efficient surface area of Ni-CP, nitrogen adsorption–desorption measurement (BET) was performed. The BET isotherms of Ni-CP and the corresponding Barrett–Joyner–Halenda (BJH) pore size distributions plot are shown in (Fig. 6). As could be seen from this Figure, the observed type-H3 hysteresis loop in the partial pressure range from 0.3 to 1.0, indicates the slit-shaped pores. The isotherm revealing type-H3 does not show any limiting adsorption at high P/P0, which is observed with spherical in shape particles42. Based on BET results, this CP catalyst has a high surface area of about 22.65 m2 g−1. Also, pore volumes and pore diameters of this CP catalyst are 0.11 cm3 g−1 and 19.34 nm respectively. The textural properties of Ni-CP which were obtained from N2 adsorption–desorption analysis are summarized in (Table 1).Figure 6N2 adsorption–desorption isotherms of Ni-CP.Table 1 Textural properties of Ni-CP.The synthesized CP materials were characterized by PXRD analysis using PW1730 instrument from Philips Company having CuKα (λ = 1.540598 Å) radiation at 40 kV and 30 mA with 2θ = 20°–100°. The XRD pattern of Ni-CP is shown in (Fig. 7). According to powder PXRD standards (PXRD, Ref. No. 01-087-0718), the crystalline peaks appearing at 42.2°, 51.3°, 75 °, 90.3° can be attributed to the (111), (300), (320), and (350) crystallographic planes of nickel crystals, which are in agreement with the previously reported works of literature 43,44. The PXRD patterns shown in (Fig. 7) confirm the successful coordination of nickel ions within the prepared framework. In addition, the (111) Ni diffraction peak with appreciable intensity further confirms the presence of Ni metal in the prepared Ni–CP45.Figure 7Normal XRD pattern of Ni-CP.The mass ratios and the thermal stability of Ni-CP were examined by the thermogravimetric analysis (TGA) (Fig. 8). In the TGA curve, the two obvious weight losses were found in the temperature range of 50–270 °C, which can be attributed to the release of the physically adsorbed moisture (water) and DMF solvents from the sample15. In this sense, it was at above 270 °C that the framework degradation started. The main weight loss at 270–340 °C was caused by the decomposition of citric acid ligand46. This result confirms the successful synthesis of Ni-CP and also indicates that the thermal stability of the sample is about 270 °C. The DSC results also support the TGA data, based on weight loss of the sample, and approve the range of temperature stability of sample.Figure 8Catalytic study of Ni-CPThe catalytic activity of Ni-CP was investigated in the multicomponent reaction for the synthesis of polyhydroquinoline and 2,3-dihydroquinazolin-4(1H)-one derivatives. In the synthesis of polyhydroquinolines, 4-chlorobenzaldehyd was selected as a model substrate to obtain the best reaction conditions. The selected model reaction was tested in various conditions (Table 2). As shown, the model reaction did not proceed in the absence of Ni-CP (Table 2, entry 1). Meanwhile, the model reaction was completed in the presence of 5 mg of this

https://www.nature.com/articles/s41598-021-03857-w

Ni–citric acid coordination polymer as a practical catalyst for multicomponent reactions